A warehouse floor is a busy place. People moving from one corner to another intermingled, with warehouse machinery sounds like a technological utopia. However, all this interaction without proper demarcation is a recipe for serious accidents and injuries. It’s common for warehouses to have floor markings, either by using colored epoxy flooring or high visibility tapes.

Any warehouse floor marking helps denote boundaries and object location, direct pedestrian flow, and bring attention to areas requiring extra care for operational and safety reasons. These warehouse floor markings are guided by OSHA floor marking requirements. Let’s take a look at what you need for concrete floor marking.

Why Is Floor Marking Important?

The single biggest reason is safety for your employees to prevent the expenses that follow injuries, and the potentially life-changing actions that occur after workplace accidents. The floor marking helps identify objects or areas of the warehouse that could pose serious safety risks to everyone working on the warehouse floor.

It also acts as a means to direct traffic around the warehouse. Doing so allows for specific pathways exclusively for pedestrian or forklift use. This deconfliction helps stop unnecessary injuries, given that 7000 non-fatal injuries and 614 deaths occurred between 2000 and 2017 as a result of forklift incidents.

In Which Areas Are Floor Markings Applied?

Floor markings are a safety requirement that OSHA expects all warehouses to adhere to. The markings assist in streamlining workflow and providing for an efficient workplace. To fully comply, the following areas need to be appropriately delineated with high visibility floor markings:

- Loading zones

- Pedestrian safe walkways

- Warehouse aisles

- Crosswalks

- Staging lanes

- Forklift traffic zones

- Vehicle traffic lanes

- Hazardous areas

- Emergency paths

- Clearance indications

- Electrical boundary areas

- Work cells

- 5s red tag areas

- Equipment charging areas

- Materials storage

- Slip or trip hazards

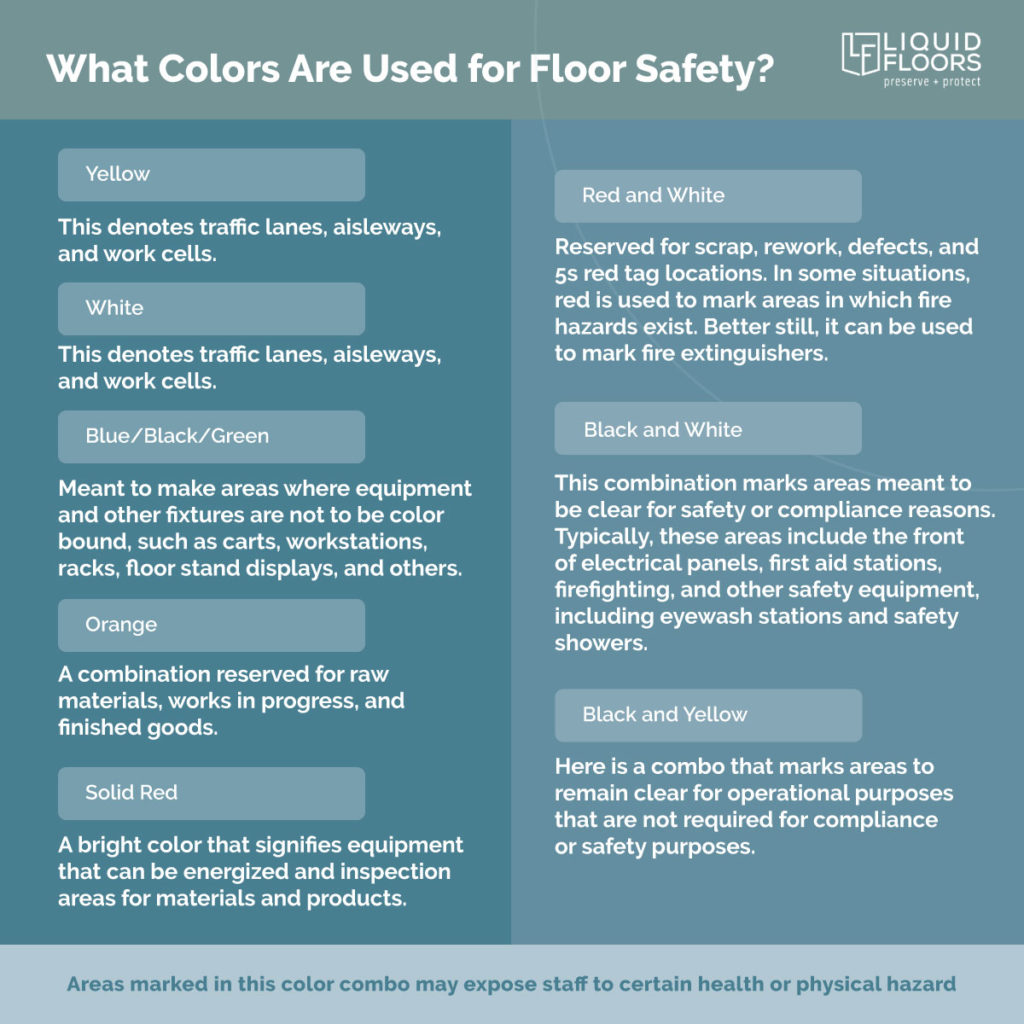

What Colors Are Used for Floor Safety?

The purpose of floor marking is to establish consistency for the zones and assist in quick and easy recognition of the message communicated. OSHA has already provided a valuable guideline for colors and their attached designations. As such, all warehouse facilities in the US follow the same floor marking standards.

Here is an outline of the colors you should use and what they mean.

- Yellow: This denotes traffic lanes, aisleways, and work cells.

- White: Meant to make areas where equipment and other fixtures are not to be color bound, such as carts, workstations, racks, floor stand displays, and others.

- Blue/Black/Green: A combination reserved for raw materials, works in progress, and finished goods.

- Orange: A bright color that signifies equipment that can be energized and inspection areas for materials and products.

- Solid Red: Reserved for scrap, rework, defects, and 5s red tag locations. In some situations, red is used to mark areas in which fire hazards exist. Better still, it can be used to mark fire extinguishers.

- Red and White: This combination marks areas meant to be clear for safety or compliance reasons. Typically, these areas include the front of electrical panels, first aid stations, firefighting, and other safety equipment, including eyewash stations and safety showers.

- Black and White: Here is a combo that marks areas to remain clear for operational purposes that are not required for compliance or safety purposes.

- Black and Yellow: Areas marked in this color combo may expose staff to certain health or physical hazards.

When laying down the markings, OSHA safety floor marking standards dictate that lines meant for safety passageways should be a minimum of 2 inches wide. For large warehouses, it’s always best to increase the width to three or four inches for increased visibility.

This increased marking width should go hand in hand with OSHA’s requirement that permanent aisles and other passageways be free from obstructions. They should also be appropriately marked in areas of operation for mechanical handling equipment.

Floor Marking Best Practices

Marking floors for safe and efficient workflow begins with understanding the meaning behind the colors. Some of these colors can work in combination, even when common sense determines that blending them can bring confusion. Here are a few best practices for warehouse floor markings.

- Yellow Lines Are Strictly For Traffic

This color is an adoption from traffic designation on state and federal roads. Yellow markings on warehouse floors are reserved for directing traffic. Icons are great at clearing up confusion about whether the lane is pedestrian or motorized.

- Consider Floor Signs

The use of icons and floor signs is an ideal way of relaying specific information such as stop signs, exit signs, yield, pedestrian crossings, etc.

- The Blue, Green, and Black Combination

While it is common practice to combine all three colors, particularly in warehouses that don’t have a lot of space to spare, it is always best to use the colors individually to help avoid confusion. An icon can further add clarity after settling on which color to put down.

Pros and Cons of Floor Taping vs Colored Epoxy Floor Marking

Using floor tape and colored epoxy both have their advantages and disadvantages. Which you settle for is dependent on your operations and other needs. Here’s a quick look

Pros of Epoxy Flooring

- Great appearance

- Resistant to damage from wear and tear

- Durable in the long term

- Easy to customize epoxy floor marking

Cons of Epoxy marking

- Depending on floor prep and application, epoxy may have a hard time adhering

- Higher costs of floor preparation and epoxy application

- Epoxy flooring is difficult to modify

Pros of Floor Marking Tape

- Quick to apply and doesn’t cause extended downtime. You can open up to traffic immediately after application.

- The floor tape maintains its color over time, provided it is cleaned the right way.

- Installing tape is a two-step process; laying it down and then tamping it by driving over it with a forklift. This allows the tape to create a durable bond.

Cons of Floor Tape Marking

- The adhesive has a tendency of shrinking

- When you want to modify the lanes, removing the tapes means leaving a sticky residue behind

- Tape isn’t as resistant to wear and tear, such as ends that have to deal with pallet traffic

- Cost per yard of tape is more expensive

What is the Best Option for Marking Warehouse Floors?

If you’re looking for a quick and easy way to mark your warehouse floors, then using floor tape provides the best option. It is also easier to modify floor markings if you use tape. However, if you do not foresee any floor marking changes and want a permanent and maintenance-free solution, the colored epoxy floor markings are your best bet.

Are You in Need of Warehouse Floor Marking?

Operating in a warehouse that’s compliant with OSHA recommendations is crucial for avoiding the steep fines and other consequences you may face.

When marking your warehouse floors, you need a set of professionals who understand OSHA requirements and colored epoxy flooring and coatings. At Liquid Floors we’ve been serving the southeast United States for years, woulApprovd you like to see how we work? Get in touch with us now!