When choosing the best lab flooring, there are special considerations for every facility. Most labs need flooring that’s durable, resistant to spills, and long-wearing. Most labs will also need flooring that can help maintain a controlled environment and reduce potential contaminants.

Some labs may have additional electrostatic requirements, require extra fireproofing, or need heat-resistant flooring options. Because of these unique factors, many labs opt for waterproof, seamless floor coating options such as epoxy, resin, or vinyl. But what’s the difference between all your lab flooring options? And which option is the best for your facility?

Understanding the characteristics of each laboratory flooring material, along with the pros and cons, can help you determine which one is the best for your space.

What Is the Best Flooring Solution For a Lab?

When it comes to lab flooring, the best solutions will offer benefits such as:

- Prevent dirt and liquid penetration into the subfloor

- Resist punctures or scrapes from dropped tools or moving carts

- Be easy to clean and maintain to a high standard

- Slip-resistant for the safety of staff

- Resistant to chemicals, bacteria, and microbes

- Durability for a long-lasting finish and a reduced ecological footprint

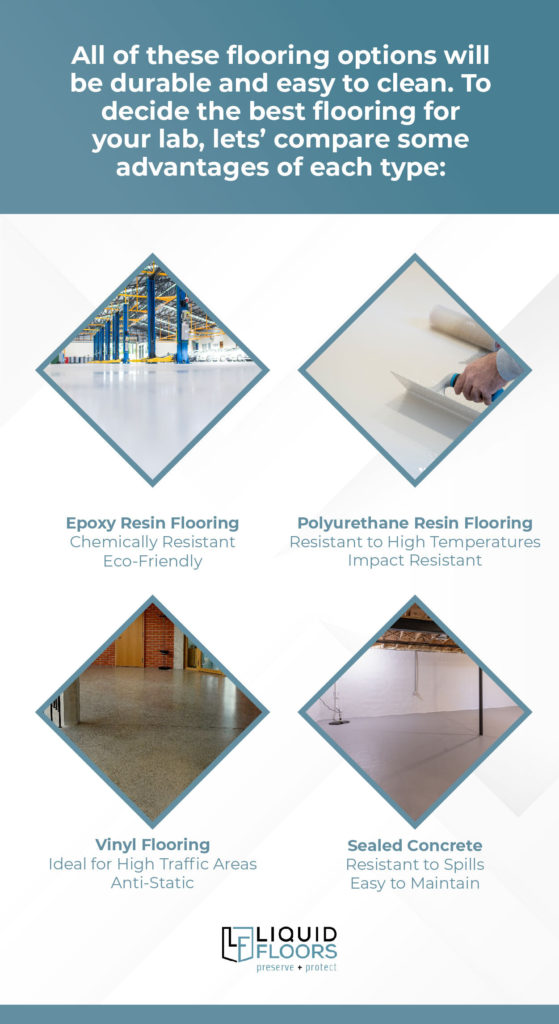

Epoxy, polyurethane, vinyl, and sealed concrete can offer these benefits. Depending on your type of lab, specific working conditions, and budget, one may be better than the others for your facility.

Epoxy Resin Flooring

Epoxy resin is a popular option for lab flooring. Epoxy resin is a two-part liquid mixture that is poured onto a prepared subfloor, then allowed to harden and cure. The finished result is self-leveling and offers a professional, long-lasting, and seamless finish.

The flooring can be chemically-resistant, making it a perfect option for chemical labs. It’s very durable and easy to clean. When applied correctly, epoxy flooring for a laboratory can last 10+ years. With proper maintenance, your floors can last even longer. It’s also very easy to re-coat when the time comes, so there is no need to remove the old flooring beforehand. That makes it more eco-friendly.

The potential downsides of epoxy flooring are the time and expense they require. Epoxy floors can take time to install because they need several coats of liquid epoxy to create the final look for the floor coating, and each layer needs time to dry. Epoxy is also an expensive liquid flooring option, resulting in a higher up-front cost.

However, when factoring in the longevity and performance of the floor coating, many labs find epoxy to be a cost-effective solution. In some cases, the application of epoxy resin can help a business avoid tearing out a damaged subfloor, saving them from that additional expense.

Polyurethane Resin Flooring

Like epoxy floor coatings, polyurethane resin is applied by mixing the base liquid coating with a hardening agent and allowing it to cure into a smooth, level, and seamless floor coating. Polyresin floor coatings’ advantages over epoxy are that poly floors are more heat resistant.

That makes them an ideal solution for labs that deal with instruments and equipment at high temperatures. This resin flooring is so resistant to heat damage it can even be used in front of ovens. It’s also an ideal floor coating for impact resistance and easy clean-up, like an epoxy resin floor.

The cost of a polyurethane resin floor will be similar to that of an epoxy floor. Polyresin floor coating requires time to dry, harden, and cure, too, so there are downtime considerations to take into account. However, the final product should last for 20 years or more and quickly fix minor touch-ups.

Vinyl Flooring

Vinyl is another excellent lab flooring option. Unlike the vinyl flooring you might have in your home, vinyl flooring for a laboratory is heat-sealed to create a seamless flooring surface. Vinyl is durable and ideal for high-traffic areas, such as those that experience a lot of foot traffic, carts, or even forklifts. Vinyl is also anti-static, like resin floors, making it an excellent option for labs with sensitive electronic equipment.

While vinyl can be one of the most cost-effective solutions for laboratory flooring, it’s important to note that it’s not an ecologically friendly one. Vinyl isn’t biodegradable. If you damage part of the floor, you’ll need to throw out the entire panel and have a new one installed. If you opt for a vinyl floor, you’ll want to make sure you aren’t under any obligation from your building certifications to pick a greener option.

Sealed Concrete

Sealed concrete can be a good alternative for a lab where cost is a major consideration. Sealed concrete is less expensive than either a resin option or vinyl flooring. Sealed concrete is first prepped by sanding the concrete floor, which is usually already in place as a subfloor. It’s then polished and sealed to create a flat, glossy finished look. It’s durable and easy to maintain, and with the right sealing process, it can last for decades while retaining its resistance to spills.

Sealed concrete can be a fraction of the cost of epoxy flooring. Be aware, though, that for the best results, your existing concrete needs to be in good condition. If your subfloor has cracks or extensive damage, it may take additional labor or a new concrete floor to achieve the best results for your lab. That can quickly drive the cost up. Sealed concrete can be more prone to cracking due to the material shrinking and expanding in temperature changes, too. If your lab experiences temperature fluctuations, sealing concrete may not be the best option.

Find the Best Lab Flooring Option for Your Facility Today

Still not sure which laboratory flooring solutions are right for your facility? The Liquid Floors team has helped thousands of commercial and industrial facilities find the right floor coating options based on their specific needs and requirements.

Whether you need epoxy flooring for a clean room or sealed concrete for your storage space, we can help. Get in touch with the Liquid Floors team today and let our experienced, knowledgeable team find the right solution for your lab floor.